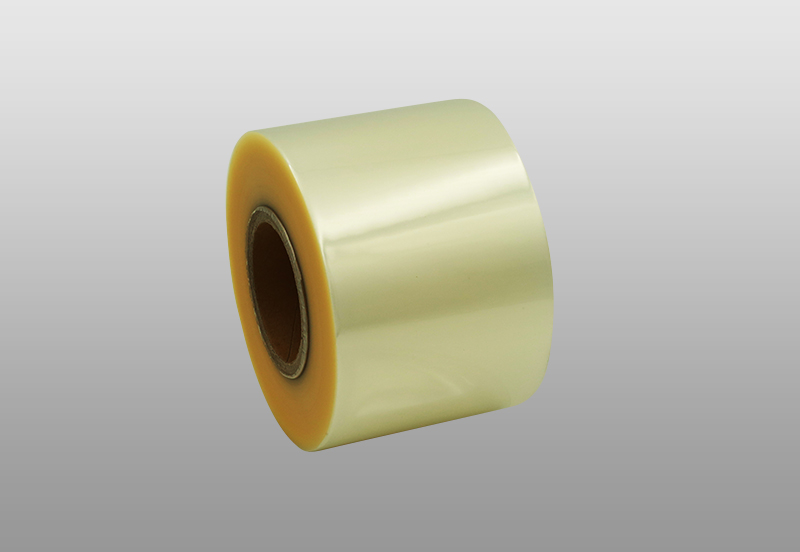

High temperature resistant PE film is a kind of film that can be retorted and sterilized under the conditions of 120°C and 135°C. It is divided into semi-retort type and high-temperature retort type. PET/AI/RPP, PA/RCPP, etc., among which the most important basic substrate is RCPP, which also has specific requirements for the characteristics of such high temperature resistant PE films. Let's take a look.

In terms of raw material resin, RCPP usually uses PP and PE block copolymerized resin, and is processed into RCPP film by multi-layer co-extrusion casting. The notable feature is that the thermal shrinkage rate under cooking conditions is relatively small, generally below 1.5%. Therefore, the thermal shrinkage rate of PET and PA substrate films used for high temperature resistant PE film packaging under retort conditions should also be at the same or similar level as RCPP. In this way, the retort-resistant packaging material can still maintain the flat appearance requirements after the retort treatment, and obtain a basic guarantee.

In terms of heat resistance, adhesives with corresponding heat resistance must be selected! High temperature resistant PE film can be divided into two categories: plastic/plastic composite and aluminum/plastic composite. several. Films with different composite structures and heat treatment temperatures need to choose different adhesives! At the same time, heat treatment tests with corresponding conditions should be carried out before mass production to verify whether the selected adhesives and substrates are suitable for the processing and application conditions of the company and downstream customers.

Choosing a suitable adhesive is only one of the basic conditions, and the heat resistance of the composite substrate is also another issue that must be considered. For composite substrates, its heat resistance is not only manifested in the melting point of the substrate itself, but more importantly, the longitudinal and transverse thermal shrinkage index of the substrate under the corresponding heat treatment conditions! In general, the thermal shrinkage rate of the substrate under the corresponding heat treatment conditions should not be greater than 1.5%, and the difference in thermal shrinkage rate between substrates should not be greater than 0.5%!

English

English 中文简体

中文简体 Español

Español русский

русский